CG SERIES : REXROTH HYDRAULIC CYLIDER TIE ROD CYLINDER

Rexroth Hydraulic Cylinder - Tie Rod Cylinder รุ่น CG Series กระบอกไฮดรอลิก แบบกระบอกสี่เสารั้ง สินค้าอุปกรณ์ไฮดรอลิกจาก Rexroth สินค้ามาตรฐานโลก ระดับสากล จัดจำหน่ายโดย นิวแอนด์ไฮด์ จำกัด ตัวแทนจำหน่ายอย่างเป็นทางการในประเทศไทยของ Rexroth (Rexroth Thailand)

รุ่น CG70

- Series 70

- Component series 1X

- Nominal pressure 70 bar

- Piston Ø 25 … 200 mm

- Piston rod Ø 12 … 140 mm

- Stroke length up to 3000 mm

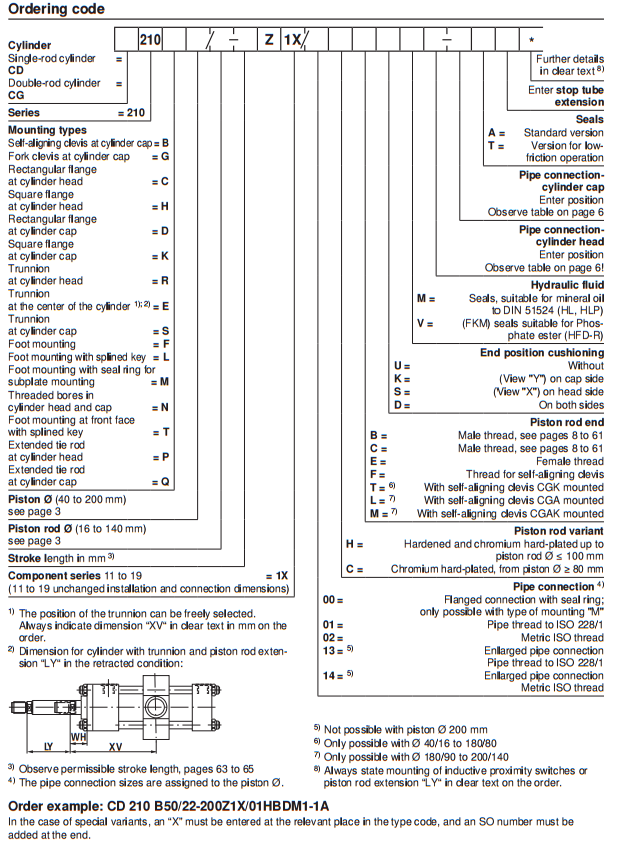

รุ่น CG210

- Series 210

- Component series 1X

- Nominal pressure 210 bar

- Piston Ø 40 … 200 mm

- Piston rod Ø 16 … 140 mm

- Stroke length up to 3000 mm

รุ่น CGT3...Z-3X

- Series T3

- Component series 3X

- Nominal pressure 160 bar

- Piston Ø 25 … 200 mm

- Piston rod Ø 12 … 140 mm

- Stroke length up to 3000 mm

Your Lift

Your Lift