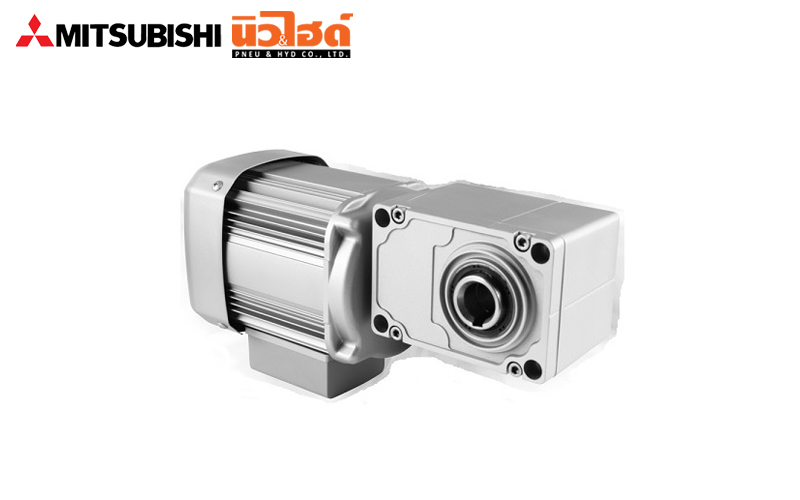

MITSUBISHI Gear Motor - GM-SSY series

Gear Motor - GM-SSY series

ดาวน์โหลดไฟล์ PDF

Feature | Gear Motor - GM-SSY series

- Exxellent drive characteristeristcs of the inverter

- Achieves a wide constant torque range in standard modle with the use of Mitsubishi inverters

- Low nouse

- A noise Level lower than conventional models has been achieved by the smooth power transmission made possible by the optimum Super Helicross gear design (Lower by 3 to 4 dB (A) compared to conventionnal Mitsubishi Models).

- Microminiaturization

- The distance from the output shaft to the case end face (dimension C) has been minimized to the smallest size possible, enabling the motors to be installed easily on small-sized machines.(Dimemsion C is the same for the three faces.)

- Shared methods for munting

- The motors are designd to designed to allow both flange and face-munting methods. Changing the methld for connecting with machines will not require a change of the motor model.

- In the case of flange mounting use the M 8 hexagon socket head cap screws. (Make sure to use the supplied special washers.) * the bolt hole diameter conforms to JIS class 1. please chack the mounting dimensions beforehand.

- IN the case of face mounting Use M 10 bolts

Specifications | Gear Motor - GM-SSY series

| Gear Motor Model | GM-SSY series | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Output | 0.1 to 0.4 kW | ||||||||||

| Number of poles | 4 P | ||||||||||

| Number of phases | 3-phase | ||||||||||

| Voltage | 200/200/220 V | ||||||||||

| Frequency | 50/60/60 Hz | ||||||||||

| Gear ratio | 1/7.5 to 1/60 (See the model configration list.) | ||||||||||

| Rating | Continuos | ||||||||||

| Heat resistance class | 120 (E) | ||||||||||

| Starting method | Dieect start | ||||||||||

| Casing construction | Totally-enclosed fan-cooled type (totally-enclosed type only for 0.1 kW models) | ||||||||||

| Protective construction | Indoor type (equivalent to IP44) | ||||||||||

| Output Shaft | Hollow shaft | ||||||||||

| Mounting method | For both flange and face mounting mehods | ||||||||||

| Mounting direction | Installation in any direction | ||||||||||

| Installation location | INdoors (without corrosive gas, oil mist, flammable gas and dust) | ||||||||||

| Ambient temperature | -15 to 40 ๐C (non condensing) | ||||||||||

| Ambient humity | 90 % RH less | ||||||||||

| Altitude | 1000 m or less above sea level | ||||||||||

| Vibration | Normally : 4.9 m/s2 or less Instantaneously 9.8 m/s 2 or less | ||||||||||

| Brake type | DC spring brake | ||||||||||

| Applicable Standards | JEC, JEM | ||||||||||

| Lubrication method | Grease lubrication (filled with TOUGHLIX GREASE GM) | ||||||||||

| Paint color | silver (equivalent to Munsell N 6.0) | ||||||||||

| Accessories | Output shaft protective cover and special washers | ||||||||||

Your Lift

Your Lift