Hiwin Shaft Motors - LMTD series

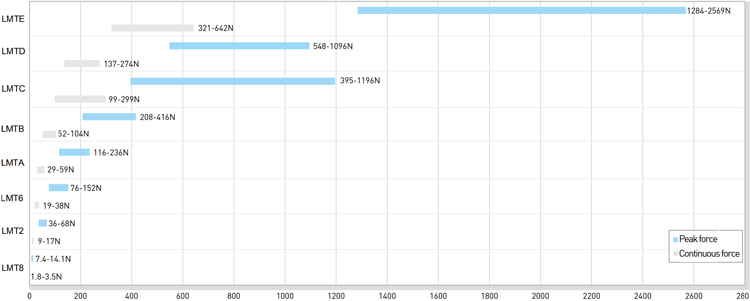

The HIWIN LMTD series: LMTD = Diameter of stator = 42.7mm, Peak = 548N - 1096N, Continuous = 137N - 274N

Linear Shaft Motors - LMTD series

The HIWIN rod-shaped linear motor has a variety of size series, with complete specifications, and easy installation. The maximum peak force for this motor is up to about 2570N. It complies with international safety CE certification, has dustproof and a waterprood IP66 rating. Using direct drive technology, on other mechanical conversion components arr needed to acieve linear tranmission, with high-speed, no cogging and low velocity ripple along with other characteristics including; excellent dynamic performance, no wear, zero backlash, and easy maintenance. Compared to traditional mechanical linear solutions, the motor effectively enhances machine equipment production capacity and reduces maintenance costs to meet the needs of high-precision positioning control and smooth operation applications such as high-speed light-load automation equipment, dust-free environment, automation equipment, panel equipment, optical inspection equipment, tool line cutting equipment, scanning electron microscope equipment, medical automation and other industries.

ดาวน์โหลดไฟล์ PDF

Feature | Shaft Motors - LMTD series

- Excellent dynamic characteristics : no cogging

- Low velocity ripple

- Max. Acceleration up to 5G

- CE certification

- Ingress Protection rating : IP66

- No wear, zero backlash

- Similar to screw mechanism, easy to install

Force Chart | Shaft Motors - LMTD series

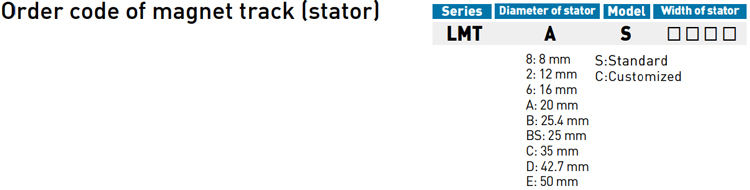

Code | Shaft Motors - LMTD series

Specifications | Shaft Motors - LMTD series

| Detail | Symbol | Unit | LMTD2 | LMTD3 | LMTD4 |

|---|---|---|---|---|---|

| Continuous force | Fc | N | 137 | 205 | 274 |

| Continuous current | Ic | Arms | 1.9 | ||

| Peak force (1s) | Fp | N | 548 | 820 | 1096 |

| Peak current (1s) | Ip | Arms | 7.6 | ||

| Force constant | Kf | N/Arms | 72 | 108 | 144 |

| Electrical time constant | Ke | ms | 3.4 | ||

| Resistance (line to line 25°C) | R25 | Ω | 18.5 | 27.8 | 37.0 |

| Inductance (line to line) | L | mH | 62 | 93 | 124 |

| Pole pair pitch | 2T | mm | 180 | ||

| Minimum beanding radius of cable | Rbend | mm | 37.5 | ||

| Back emf constant (line to line) | Kv | Vrms/(m/s) | 44 | 66 | 88 |

| Motor constant ( 25°C) | Km | N/√W | 13.7 | 16.8 | 19.4 |

| Thermal resistance | RTH | °C/W | 0.7 | 0.5 | 0.4 |

| Thermal switch | - | - | PTC | ||

| Maximum DC bus voltage | - | VDC | 325 | ||

| Mass of forcer | Mf | kg | 3.9 | 5.9 | 7.8 |

| Unit mass of stator | Ms | kg/m | 7.4 | ||

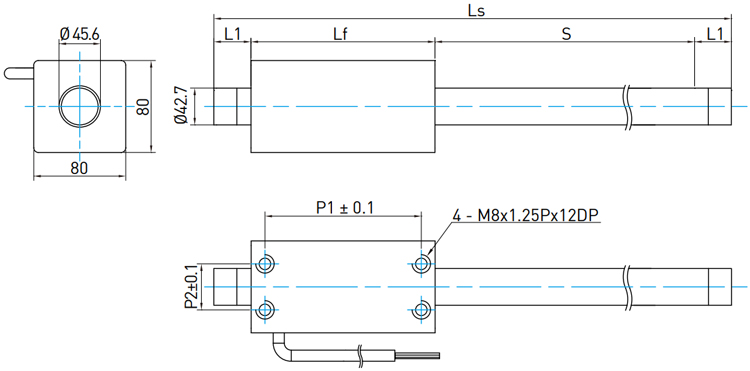

| Length of forcer | Lf | mm | 220 | 310 | 400 |

| Mounting pitch | P1 x P2 | mm | 200 x 50 | 290 x 50 | 380 x 50 |

| Stroke | S | mm | 100 ~ 2000 (Take 50 mm as increase unit) | ||

| Clamping length | L1 | mm | 60 (Stroke = 100 ~ 550 mm) 80 (Stroke = 600 ~ 1000 mm) 100 (Stroke = 1050 ~ 2000 mm) |

||

| Total stator length | Ls | mm | Ls (Total stator length) = S (Stroke) + Lf (Length of forcer) + 2*L1 (Clamping legnth) | ||

- Values in the table refer to operation without forced cooling.

- Except diemensions, the electrical specifications are in ±10% of tolerance.

- We reserve the right of changes, please follow customer recognition drawings.

Your Lift

Your Lift